Heating industry

The heating industry is a market where esthetical product quality, process reliability and flexibility caused by versatility of products are most important. RODOMACH is able to fulfill customers’ requirements and to provide the required process technology integrated in standard- and dedicated solutions as well. Our projects in the heating industry are various and mainly dedicated to the customer requirements. Some typical projects for the heating industry which we have developed i.e. laser welding installations for towel radiators and a laser welding installation for end-caps of these radiators.

For the heat exchange industry RODOMACH developed a Pillow Plate laser welding machine. The Pillow Plate (or thermo plate) consists of two steel plates, connected by laser welding. After being welded together, the plate is inflated by using water pressure. The water pressure creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating medium is conducted. All welds have to be extremely accurate and consistent. Below are three different specially developed machines shown with links for more information.

End Caps

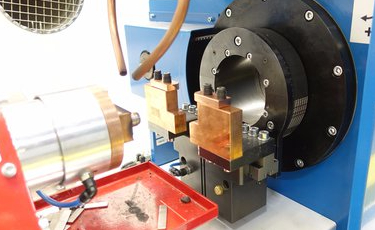

The laser welding installation consists of a loading area for the operator. After loading the individual components and releasing the installation, the welding process begins.

End Caps

Pillow Plate

RODOMACH is a system Integrator and manufacturer of Pillow Plate machines. Our company has developed into an supplier of specialized machinery.

Pillow Plate

Towel Radiators

The laser welding installation exists of the assembly and loading area. During the loading operation the laser welding station is welding the previous positioned towel radiator.

Towel Radiators