About

RODOMACH

RODOMACH is a system Integrator and manufacturer of standard and dedicated machines with focus on welding and handling processes. Our drive is to develop and deliver creative, innovative and reliable solutions to our customers.

We are an expert in the development, construction and installation of dedicated machines and robot systems combined with components like fixtures, gripper systems and peripherals. Our product range includes robotic systems incorporating high-class components. It also includes standard machines and modules up to completely automated production lines. Our dynamic approach combined with highly qualified and experienced engineers results in a strong team. From developing the installation concepts, engineering, assembly up to commissioning and including start up production; Realizing turnkey projects! We are specialized in arc welding, laser welding, spot welding, CNC machinery, positioners and assembling solutions.

Pillow Plate Laser welding machine

The Pillow Plate or dimple jacket is created by Rodomach's Pillow Plate Laser welding machine. Pillow Plates, also called dimple jacket plates or thermo plates, consists of two stainless steel sheets that are laser welded together by welding a custom circle weld pattern. Then the plate is inflated by using water pressure, which creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating is conducted. The thickness and the spot pattern are determined by the pressure requirements.

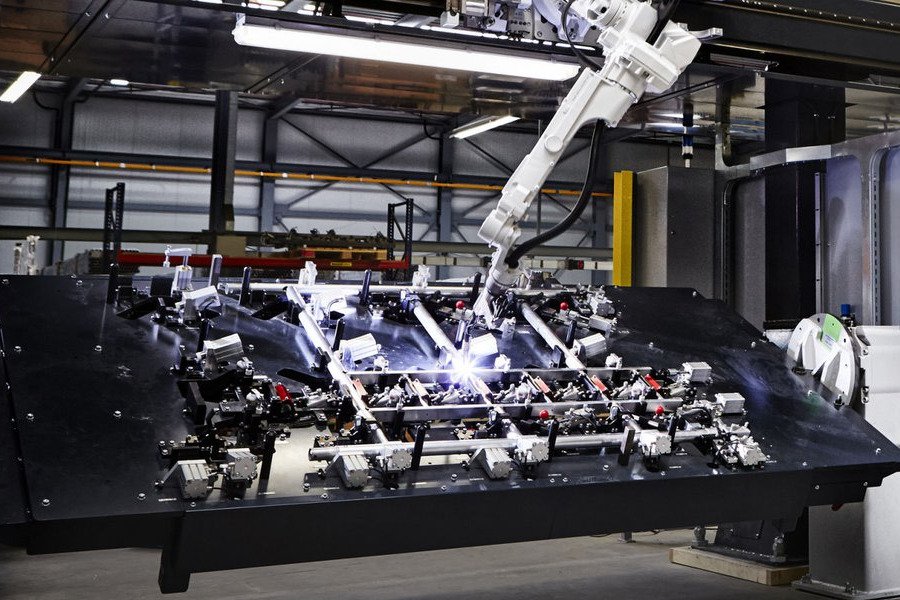

Track Robot Cell

A concept with a floor-mounted rail system is frequently required if the components being worked upon have a length of more than 2,500 mm. For length variety of products between 1,200 mm up to 4,000 mm a robot track solution is required. The arc welding robots are installed on a mobile carriage (driven by an external axle of the robot) and can thus cover the necessary work area. This concept is available as single station and multi-station as well. For this purpose, the components are fixed and positioned in dedicated welding fixtures mounted at positioners (external axes of the robot) with counter bearings.

CNC Fluting Machine

The CNC Fluting Machine is a fully automated machine has been designed for fluting a great variety of rolls with a weight up to 6500 kg. All diameters up to 813 mm can be machined. One of the main characteristics of this machine is the impressive machining speed. The back stroke of the machine runs at a speed of 1,8 meter per second. The cutting speed is completely variable which means that the speed at entrance and exit of the material can be adjusted to a lower value then the rest of the roll. In this way the machine will have a cycle time of only 40% of standard machines of our competitors.

Pillow Plates, also called dimpled plates or thermo plates, consists of two stainless steel sheets that are laser welded together by welding a custom circle weld pattern. Then the plate is inflated by using water pressure, which creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating is conducted. The thickness and the spot pattern are determined by the pressure requirements.

The Rodomach

Machine world map

Rodomach machines are all over the world, used on a daily basis by our customers. Currently we shipped our machinery to 32 different countries.