Resistance welding

RODOMACH has many years experience with resistance welding processes. Depending on the product geometries and demands we can choose the appropriate resistance welding variants such as spot welding, projection welding and medium frequency (MF) welding. These variants can be integrated in standard welding cells and dedicated machines. Defining the required resistance welding process depends on the product- and process demands. The resistance welding process can be divided in "normal" spot welding or projection welding technology.

Door Frame Installation

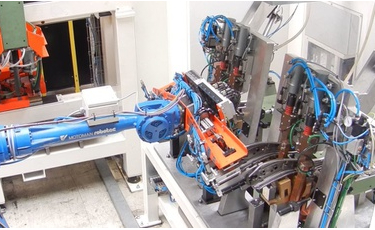

Based on the customer requirement for maximum flexibility caused by the huge variety of profile geometries RODOMACH developed a flexible spot welding installation.

Door Frame Installation

Seating Tracks Installation

For manufacturing of seating tracks RODOMACH developed several dedicated welding installations. The parts are loaded by the operator in the several welding stations.

Seating Tracks

Side Members Installation

Responsible for the entire process chain at manufacturing of seating side members. The standard arc welding robot cells positioned in line and connected with external conveyors.

Side Members Installation

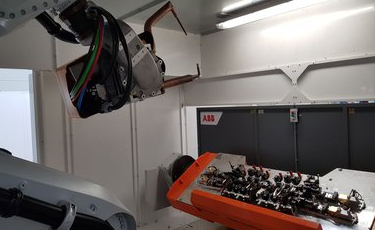

Standard Spot Welding Cell

The standard spot welding cell is developed for a wide range of product dimensions. Depending of the customer requirements the spot welding cell can be equipped with 1, 2 or 3 robots.

Standard Spot Welding Cell