Pillow Plate Laser Welding Machine

RODOMACH is a system Integrator and manufacturer of Pillow Plate machines. Our company has developed into an innovative machine builder which focuses on the development, construction and supply of specialized machinery.

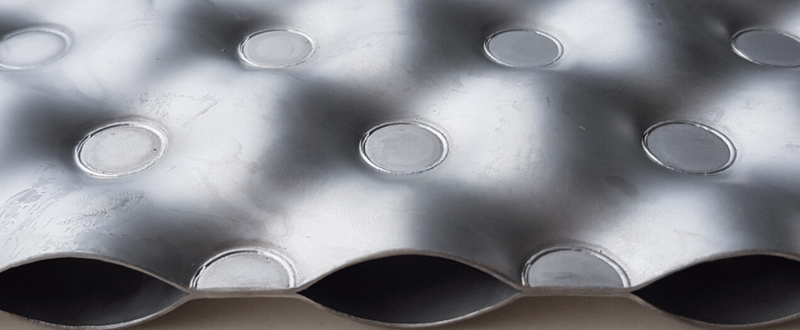

Pillow Plates, also called dimpled plates or thermo plates, consists of two stainless steel sheets that are laser welded together by welding a custom circle weld pattern. Then the plate is inflated by using water pressure, which creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating is conducted. The thickness and the spot pattern are determined by the pressure requirements.

Pillow Plate or dimpled jacket possibilities

The machine is able to produce Pillow Plates which can be used for a large range of products, such as; heat exchangers, filter housings, falling film, square containers, cooled containers, offen walls, climate chambers, ice accumulators, pipes, heated or cooled vibration feeders and in cylindrical tanks, as well as in tanks of other shapes and designs, for example rectangular or oval ones. They can also be used for various industries for example food and beverage industries and other food-making and process industries. The surface can be brushed, polished or sandblasted. Possibilities are endless because you can produce every weld pattern shape and any required plate shape can be welded or engraved. The Pillow Plates can be single or double embossed plates.

Did you know that thin plate pillow plate or dimple jackets can be used as active cooling element for batteries such as car batteries?

The Rodomach laser welding machine

The RODOMACH laser welding machine is integrated with a feeding and transport system for the pillow plates. Typical specifications of the machine are the accurate positioning and secure clamping of the product in the welding area. RODOMACH equippes the machine with a 2 KW fibre laser including "auto adjusting focus" of the laser optic. Together with the clamping devices and improvements on the gas cross jet for the 360° gas protection of the welding surface, RODOMACH has succeeded in developing a robust new generation for key hole laser welding of thermo plates. Dimensions and surface finishing is depends on the customer’s specifications and requirements. RODOMACH delivers this machine to manufacturers of pillow plates with state-of-the-art technology.

The software which guarantees the shortest and easiest work preparation

Very easy to use software PillowPlateCreator™ for automatic conversion of a drawing into the machine. The software will be installed on the machine, the customer's server and 1 PC of the customer.

Laser TRUMPF TruDisk

During the development of the machine, Rodomach Speciaalmachines B.V., has decided to use a fibre laser from TRUMPF. This type of laser, whereby the beam of light is led to the welding head through a fibre, was chosen because of the many advantages. The laser source power will be selected to meet the specifications of the customers’ requirements.