Laser Welding

Laser welding is mainly used for joining components that require high welding speeds, thin and small weld seams and low thermal distortion. Laser welding is an excellent automatic operation, very accurate and the quality is controlled online during the process. This is the reason why laser welding is a common joining method in the modern industrial production.

The weld geometry describes how the parts fit together. For example, they may overlap or placed against each other. The mechanical properties are the first thing to consider when defining the weld geometry. Is a continuous weld required, or will the weld consist of individual welding spots? Is the weld made up of a large number of short lines or lots of small circles? Here, too, the decision of which type of weld to use depends on two important factors: the required strength of the weld and the maximum amount of heat input into the component.

Diamond Tools

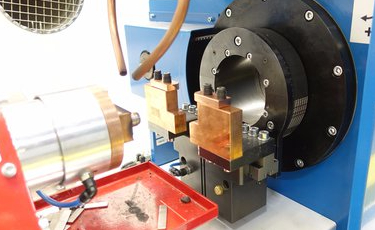

This is the fully automatic laser welding installation developed by RODOMACH. The laser welding installation consists of a loading and unloading area and a welding area.

Diamond Tools

End Caps

The laser welding installation consists of a loading area for the operator. After loading the individual components and releasing the installation, the welding process begins.

End Caps

Pillow Plate

RODOMACH is a system Integrator and manufacturer of Pillow Plate machines. Our company has developed into an supplier of specialized machinery.

Pillow Plate

Sharp Corners

The laser welding installation exists of a loading area for the operator and a welding area. After loading the single components and releasing the installation the welding process starts.

Sharp Corners

Towel Radiators

The laser welding installation exists of the assembly and loading area for the operator. During the assembly / loading operation the laser welding station is welding the previous positioned towel radiator.

Towel Radiators